EMS Scada Systems for Energy Storage Projects

SCADA Solutions Customized for Energy Storage Projects

Our SCADA systems are purpose-built to support the full scope of energy storage project requirements. At the heart of these systems is the Energy Management System (EMS), which functions as an intelligent supervisory platform that manages the dispatch of one or more energy storage or power generation units. The EMS ensures real-time monitoring and optimal performance of each system, while also enabling smooth integration and operation of multiple assets.

The EMS is designed to tackle two major technical challenges commonly encountered in large-scale energy storage management:

- Efficient scheduling of energy storage systems to ensure secure operation and achieve maximum performance benefits.

- Harmonization of diverse systems, including those of varying capacities and technologies. Since many storage solutions incorporate components from different manufacturers, the EMS plays a key role in ensuring they work together seamlessly.

EMS SCADA Solution Overview

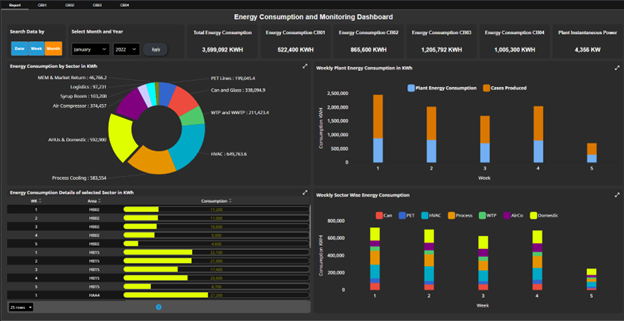

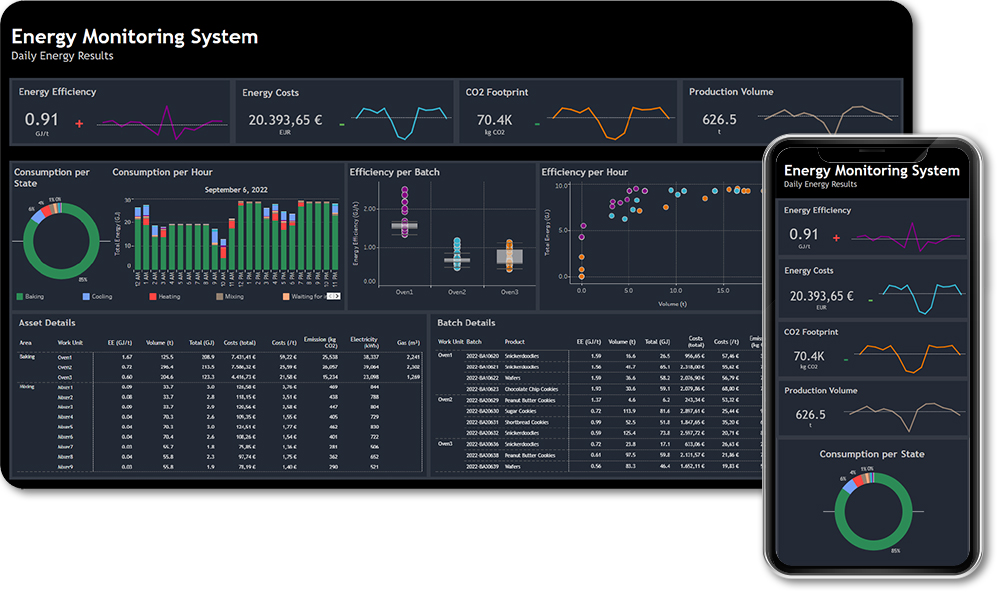

EMS SCADA HMI Graphical Interface Features:

- Accessible via web browser

- Fully customizable to meet project-specific needs

- Supports modifications to control settings and operational modes

- Displays Point of Interconnection (POI) data, including MW, MVar, voltages, and currents

- Provides detailed inverter metrics such as MW, MVar, voltages, and currents

- Monitors battery system status, including state of charge (SOC), state of health (SOH), power output (MW), voltage, and current

- Offers battery module-level visibility, including SOC, SOH, temperature, current, and voltage

- Functions as the Master Site Controller for real and reactive power dispatch, ensuring compliance with LGIA and PPA requirements

- Includes comprehensive alarm and event monitoring

Arkans EMS Solution is custom built to facilitate:

- ITC compliance: Avoid charging from Grid:

- Log all charging activity to establish 75-100% charging from renewable energy source in first five service years to fully capture the tax credits.

- Control export of PV Power to Grid per user specific maximum limit by charging ESS.

- Application to capture solar energy that is otherwise wasted during:

- Mid-day inverter clipping

- Curtailment from the utility.

- ESS discharge to meet export requirements without exceeding export requirements.

- Scheduled P/Q control of ESS at any time.

- Any additional site-specific requirements.

EMS Controller System Functions:

- Inverter Controller interface

- Supports advanced energy use cases such as load shifting and energy arbitrage

- Delivers power control features including voltage regulation, grid support services, and renewable energy stabilization

- Interfaces with both rack-level and central battery management systems (BMS)

- Oversees battery functions such as charging, discharging, balancing, and maintaining state of charge (SOC)

- Detects and reports alarms at both the overall system and individual component levels

- Enables fast, automated remote shutdown to ensure operational safety

- Provides data exchange with client systems through standard communication protocols like OPC-UA and DNP3

Hardware:

-

- Windows based Virtualized or Standalone Servers for SCADA and Historian

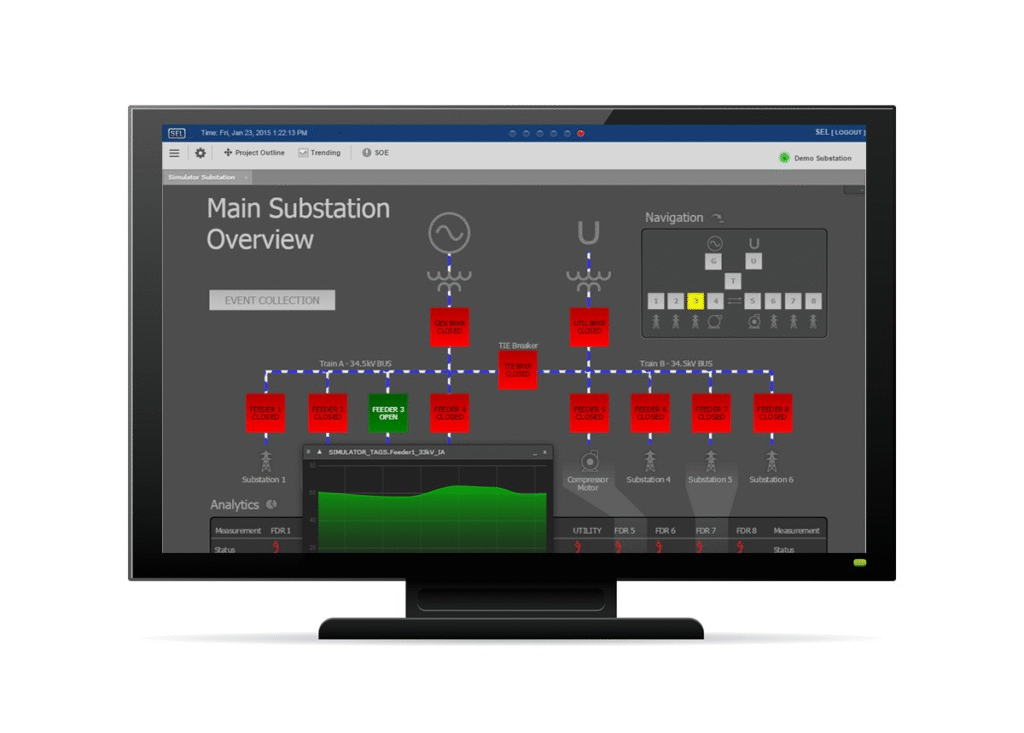

- SEL-3555 – PLC as Power Plant Controller

- Full SCADA rack with single or redundant PLC(s)

- Field Network communication enclosures

- MET Stations (if solar on-site)

Software:

- Inductive Automation – Ignition HMI + Perspective

- Windows based Virtualized or Standalone Servers for SCADA and Historian

- SEL RTAC – PLC as Power Plant Controller

- Full SCADA rack with single or redundant PLC(s)

- Field Network communication enclosures

- MET Stations (if solar on-site)

On-site Integration and Testing:

- Factory Acceptance Testing (FAT)

- On-site commissioning support

- Site Acceptance Testing (SAT)

- Remote engineering and testing support through COD and Energization

Operator Training:

- Remote, site specific SCADA system training (hardware and software)

- Additional training options available upon request

On-going Maintenance and Support:

- Telephonic support

- Monitored email support (ticketing)

- Remote assistance using Remote Desktop and a Virtual Private Network

- Planned or Emergency On-site Support

- Quarterly system health check

SCADA Support Services

Arkan’s SCADA support services allows end users to utilize Arkan’s dedicated team of experienced and knowledgeable engineers through a more proactive approach. Our team will have secure access to the operational system and will be readily available for any support or troubleshooting needs that arise through day-to-day operations. Utilizing this approach will ensure your systems will have the support they need to perform efficiently on a consistent basis.

We offer remote, software-level troubleshooting and support for the SCADA system’s network, alarms, and all connected devices within the local infrastructure. This support includes, but is not limited to, components such as

- Inverters

- MV Transformers

- Trackers

- Substation IEDs

- Weather Stations

- Metering

Additional support services may be provided upon request and subject to owner approval. These services include:

- modifications to HMI and SCADA point lists

- project recovery and system restoration

- adjustments to logic and control tuning

- support for substation IEDs

- On-site field technician assistance is also available as needed, based on customer request.